Newsroom

Vape fires cost waste, recycling sector $2.5B yearly - E-Scrap, Recycling: December 9, 2025

Waste and recycling operators are heading into another year of elevated fire risk as lithium-ion batteries from electronics and disposable vapes continue to slip into waste streams, according to fire-tracking consultant Ryan Fogelman.

He said the sector is still dealing with what he calls the vape effect and argued that the next phase of the response has to involve tobacco and vaping companies directly. Fogelman, vice president of fire protection at Fire Rover, has been compiling and publishing data on publicly reported waste and recycling facility fires in the US and Canada since 2016.

His reports show that incident counts have climbed sharply in recent years as battery-powered devices proliferate and as disposable vapes move from ashtrays and pockets into bins, trucks and tipping floors. In a recent fire report, he wrote that the average number of facility fires in the current four-year span is noticeably higher than in the previous six years and that vapes are a major contributor to that increase.

ESA: Battery fires reaching ‘epidemic’ levels - Let's Recycle.com: September 17, 2025

The Environmental Services Association (ESA) has issued a stark warning that battery fires in the UK’s waste sector have reached “epidemic levels”.

In a policy briefing, the ESA called for urgent reform to mandate universal kerbside collections for waste batteries and small electricals.

Material Focus reported that more than 1,200 battery-related fires broke out in refuse vehicles and waste facilities during 2023/24 – a 71% increase on the previous year.

The trade body says these incidents are now costing the UK over £1 billion annually, threatening not only vital infrastructure but also the lives of frontline workers tasked with managing the nation’s waste.

Australia opens world’s first battery-in-device shredding plant -E-Scrap News: September 11, 2025

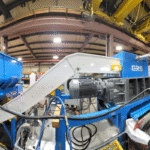

A new Battery-in-Device Shredding (BIDS) facility in Melbourne will start operations shortly, according to its backers, who say the site will tackle the growing problem of batteries hidden in everyday products and the risks they pose when discarded. EcoBatt, a subsidiary of the EcoCycle Group, this week unveiled the BIDS unit in Campbellfield in north Melbourne. The project received Australian $2 million (US $1,317,240) from the Victorian Government’s Circular Economy Infrastructure Fund, which is delivered by Sustainability Victoria under the Recycling Victoria plan. Environment Minister Steve Dimopoulos joined EcoCycle Group CEO Doug Rowe for the opening, which the company framed as a global first for embedded-battery processing. The BIDS system was developed by Gloyd Recycling Solutions, a US firm focused on automating recovery of embedded power cells.

Sustainability Victoria - LinkedIn Post: September 4, 2025

Australia’s first dedicated Battery‑in‑Device Shredding (BIDS) plant has launched in Melbourne's north – supported by a $2 million grant from Sustainability Victoria, on behalf of the Victorian Government.

EcoCycle opens battery recycling facility - InsideWaste: September 3, 2025

Victoria is now home to a first of its kind battery recycling facility that will process batteries found in household items and divert over 8,000 tonnes of waste per year from landfill. Minister for Environment Steve Dimopoulos announced the opening of the first dedicated battery-in-device shredding plant in Australia.

EcoBatt (ANZ) - LinkedIn Post: September 3, 2025

Today we held the official opening for the nation’s first Battery-in-Devices Shredding (BIDS) Plant in Campbellfield, Melbourne — a groundbreaking solution to one of the fastest-growing waste challenges of our time. From vapes and power tools to phones, toys, wearables and more, hidden batteries are everywhere. When thrown in the bin, they can spark fires, cause explosions causing harm to our environment. Our new facility safely processes these batteries and recovers over 90% of valuable materials for reuse, setting a new benchmark for battery safety and recycling infrastructure in Australia.

Company debuts battery-containing device shredder - E-Scrap New: June 26, 2025

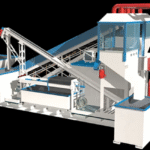

Seeing the lack of smaller-scale systems suited for processing small personal devices containing lithium-ion batteries, Houston-based Gloyd Recycling Solutions developed what it says is the first marketed device to shred battery-containing devices of laptop size and smaller.

Vapes and solar panels have driven a 75pc surge in electrical device sales over the last five years, new data shows today - WEEE Ireland: June 19, 2025

A total of 93 million household electronic items were purchased in 2024 – almost three times the volume sold in 2006, according to WEEE Ireland as it launched its 2024 Annual Environmental Report this week. The massive surge includes a reported 31 million vape and e-cigarette devices sold last year alone, and 2.5 million solar PV panels installed in the last five years.

Vapes made up 33% of electrical devices sold in 2024: Monday, 16 Jun 2025

Found on Raidió Teilifís Éireann, Ireland's National Public Service Broadcaster: The public has been urged to recycle vapes and e-cigarettes as a report showed they made up one-third of all electrical devices sold in Ireland last year. The report, by Waste Electrical and Electronic Equipment Ireland (WEEE Ireland), found that around 1.1m vapes were recycled in 2024 but around 31 million were sold across the country.

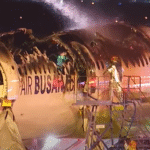

Lithium-ion batteries are causing a dramatic rise in fires on airplanes - KQHA News May 19. 2025

WASHINGTON (SOA) — Joseph Fleck calls it the scariest flight of his lifetime. "I hear a loud yell, 'Hey, there's a fire!'" Fleck said. "I looked up immediately and quickly saw the cabin filling with smoke and this very nasty smell." It is a situation that highlights the prevalence and dangers of lithium-ion batteries. People use them every day. In fact, travelers bring an average of four of these devices on board every time they fly. But there's been a dramatic rise in fires triggered by these batteries on board flights, and experts warn more needs to be done to avoid a disaster.

A hot topic for recyclers: Battery-related fires - Resource Recycling May 14, 2025

Many MRF operators cite batteries as their greatest challenge, and for good reason. Fires at waste management facilities have been steadily increasing in recent years, many traced back to improper disposal of household batteries. During a May 7 webinar hosted by the Northeast Recycling Council, speakers from two information technology asset disposal firms as well as the U.S. EPA explored a wide range of efforts to help improve consumer education and reduce fire risks.

Battery Recycling Plant Burns Again — One Year Later! April 9, 2025

On April 9, 2025, a massive fire broke out at the former Fenix Battery Recycling facility in Kilwinning, Scotland—almost exactly one year after the first fire on April 8, 2024. This video breaks down what happened, why the site was still packed with lithium-ion batteries a year after the initial blaze, and how poor storage practices, bankruptcy, and regulatory inaction all played a role in this entirely preventable second fire.

Evacuations lifted after Lithium-ion fire in Hillyard: Feb 25, 2025

A fire at a lithium-ion battery facility in Hillyard caused some evacuations on Tuesday morning and sparked hazmat concerns.

A California Battery Plant Burned. Residents Have Gotten Sick, and Anxious. - The New York Times: Feb 10, 2025

This article covers the negative environmental & health effects that residents are feeling in the aftermath of the 2025 Moss Landing Battery Fire; how current tests prove the presence of heavy metals (including cobalt, nickel, copper) that exceed EPA risk levels; how these metals could be detected over five miles away from the site in the air, water, and soil; how the fire has increased concerns over the safety of lithium-ion battery storage plants despite California's push for clear energy; and the potential economic impacts the fire may have on agriculture and farmworkers.

Fire at one of world’s largest battery storage facilities sparks safety concerns - Straight Arrow News: Jan 27, 2025

A significant California fire at the Moss Landing Power Plant in Monterey County, one of the world’s largest lithium-ion battery storage facilities, has raised concerns about the safety of such sites among local leaders. The heightened fears come as California increasingly transitions to renewable energy and electric vehicles, both of which require these batteries to function.

Lithium Battery Fire: Missouri’s Largest Recycling Plant Explodes! Nov 3, 2024

The largest lithium-ion battery recycling facility, in the world just went up in flames, and explosions were caught on video. Critical Mineral Recovery was located in Fredericktown, MO. I’ll walk you through the details, share insights from experts, and discuss the big questions around safety protocols, fire containment, and the potential impact on local residents. This fire could even lead to a Superfund site designation – here’s what you need to know.

Panelists: Battery rules should be proactive, not reactive - E-Scrap News: Oct 24, 2024

Legislative action on batteries is speeding up, but some of those laws are missing their marks and creating a regulatory environment that is difficult to recycle in, panelists said at the recent E-Scrap Conference in Orlando.

Amos Manufacturing part of battery recycling technology effort - Recycling Today: May 15, 2024

Alpena, Michigan-based Amos Mfg. Inc. and Gloyd Recycling Solutions LLC (GRS) have announced a collaborative effort to bring technology called the Battery-In-Device-Shredder system (BIDS23) into production. According to the companies, the system is integral to improving safety and reducing manual battery removal from small electronic devices by directly processing batteries that can present a fire hazard in recycling and solid waste settings.

The Circular is Here! / The e-Stewards Newsletter - March / April 2024

e-Stewards welcomes Gloyd Recycling Solutions (GRS), a new ITAD disposition consultancy, to the ranks of its Enterprise Program. With over twenty years of experience in environmental services, waste management, and recycling in both the public and private sectors, GRS has the knowledge, established history, and partnerships to support every aspect of the recycling industry.

Firms develop battery-in-device processing system: Jan 5, 2024

Sending battery-containing devices through the shredder is typically a no-no for several reasons, but manually removing and taping batteries prior to shredding the rest of the device is labor intensive. A newly unveiled processing system addresses the conundrum.

Experts discuss the industry's e-plastics crossroads - E-Scrap News: December 5, 2023

The Basel Action Network (BAN) and its certification standard, e-Stewards, recently put the e-scrap industry on notice that exporting mixed e-plastics – currently a widespread industry practice – is illegal under the Basel Convention.

The North American Hazardous Materials Management Association: Growing Through Affiliations - Waste Advantage Magazine: Oct 31, 2023

NAHMMA recognizes the benefits of a collaborative partnership with organizations sharing similar goals and has developed an Affiliate Agreement as a means to exchange expertise, resources, and ideas to advance the hazardous materials management profession.

By Jeff Gloyd, GRS

EPR/Legislative Updates

SB 1215 Covered Battery-Embedded Products - CalRecycle: July 10, 2025

Governor Newsom signed Senate Bill (SB) 1215 into law to reduce battery fires and injuries to sanitation workers and to ensure that batteries are collected for recycling rather than ending up in the waste stream. Reusing and recycling as many materials sold in California as possible is vital to the state’s larger effort to build a circular, remanufacturing economy that turns pollution sources into new materials

Right to repair in WA and battery EPR in Nebraska - EScrap News May 22, 2025

Governors in Washington and Nebraska signed e-scrap bills into law recently, giving Washingtonians the right to repair their consumer electronics and Nebraskans an extended producer responsibility program for batteries. LB 36, the Safe Battery Collection and Recycling Act, marks Nebraska’s first EPR attempt, according to the Nebraska Recycling Council. It was signed into law on May 20 after passing a final reading vote of 43-6 on May 14. Executive Director of the Nebraska Recycling Council Kim Carroll Steward told E-Scrap News the passage of the bill “is a major win for safety, economic, and environmental protection in Nebraska.”

Battery EPR passes in Colorado - EScrap News May 16, 2025

Colorado is adding extended producer responsibility for another material stream to its state laws, this time for batteries. SB 163 passed both chambers with bipartisan support and is now on the governor’s desk. The final votes on the House-amended bill were 44-21 in the House and 23-12 in the Senate on May 6. It had initially passed the Senate on April 29 on a vote of 21-11 with three abstaining. Recycle Colorado said in a statement that “we want to give a special thanks to everyone who helped us talk to our legislators about the importance of keeping batteries out of the trash and recycling and capturing the materials to be used in future batteries.”